| revised 2nd of Oct 2011 PM added Machlett tube

measurements, Dentron, rules, and warnings revised 23 Feb, 2013 for some minor wording clarity |

The purpose of this page is to present the full unedited Eimac Filament Management program to readers as applicable to amateur radio amplifier systems, and to show proper filament voltage measurement techniques before people injure or electrocute themselves, diminish amplifier performance, or damage tubes.

Rules for Setting Filament Voltage

No exceptions. Before setting filament voltage we must know and account for the following:

1.) Proper filament voltage range, or best target voltage. This either comes directly from tube data sheets or directly from the equipment manufacturer.

2.) RMS voltage at tube pins in a fully warmed amplifier for a given power line voltage. This has to be true RMS voltage, not a calculated RMS from a typical averaging meter. With higher current filaments, it is critical to know the voltage on the tube pin. Knowing voltage some distance away, even a few inches, is not correct.

3.) Full power line voltage range at the equipment location.

4.) Filament RMS voltage variation while the equipment is operating under maximum power, or at idle. This is critical.

|

Warning: Low filament voltage can result in faster emission loss than excessive voltage. Do not assume we can blindly adjust filament voltage to some nominal voltage without knowing and accounting for all of the above rules! For example, Dentron amplifiers normally have much higher filament voltage than acceptable range. They also have very poor filament regulation with power supply loading, typically varying 3% from no load to full load on the high voltage. If we only account for minimum line voltage under no transformer load and set for minimum filament range, the filament will almost certainly fall below minimum. This increases IMD (splatter) and can shorten tube life more than too much voltage! If instructions set voltage without following the above rules, they are wrong and can cause damage. |

Filament Voltage

Most tube data sheets specify an allowable range of filament voltage. This voltage range, without question, satisfies warranty requirements and assures proper performance as related to the filament. We can move voltage outside that range only if the manufacturer approves, or if we properly verify performance. Most important and often overlooked, there are minimum and maximum voltages! While generally not mentioned on amateur radio forums and web pages, excessively low filament or heater voltages can actually be more deleterious than needlessly high filament or heater voltages.

Minimum voltages are especially critical in oxide-cathode tubes. While operation above allowable range deteriorates the very long term emission life to perhaps 60% or so for every 5% above nominal voltage, operation below safe minimum voltages will usually destroy the tube in surprisingly short order. This includes tubes like the 8877/3CX1500A7, 3CX5000A7, and 3CX800A7. I've occasionally seen amplifiers that have been modified to reduce tube filament voltage with repeated short tube life. One amateur amplifier's 8877 was set at 4.2 filament pin volts, and went through a new tube in less than one month of casual amateur operation. The brand new tube, because of low voltage poisoning, had no warranty.

Directly heated tubes (those without heater warm-up time) are more tolerant of low voltage, but not immune. In some cases, a filament management program can extend directly-heated power grid tube, but not always. One private website, and the October 2011 QST Magazine (parroting that private website), make grossly exaggerated claims of increased tube life through reduction of filament voltage to an arbitrarily created value. Unfortunately, not only are life increase promises greatly exaggerated; the target voltage is selected incorrectly, and the article's measurement methods are wrong. The result is SSB bandwidth and tube life can be compromised from excessively low filament voltage.

To comply with tube filament voltage management, the filament must be regulated within +- 3% and a host of other criteria must be met. Here is what Eimac says, in Eimac's own unedited words:

|

NOTE: If the filament voltage cannot be regulated to within ± 3%, the filament should always be operated at the rated nominal voltage specified on the data sheet. It should be noted that there is a danger to operating the emitter too much on the “cold” temperature side. It may become “poisoned.” A cold filament acts as a getter; that is, it attracts contaminants. When a contaminant becomes attached to the surface of the emitter, the affected area of the emitter is rendered inactive, causing loss of emission. |

If we cannot meet all criteria, we should use nominal rated voltage. Nominal rated voltage is given in every tube manufacturer's data sheet, and cannot be arbitrarily rewritten to a new value at whim.

Why a Voltage Range?

Power line voltage varies seasonally and with local time. Most amateur (and many commercial) products, because of size, weight, or cost, cannot use regulated AC filament supplies. Directly heated cathodes also do not work well on DC supplies. A DC supply biases one end of the filament more negative in relationship to grids, and this can unevenly distribute emission current. This is especially problematic in higher voltage filaments with low bias tubes.

Most amateur and many commercial amplifiers or transmitters employ simple step-down filament transformer systems. While filling a cost and space limit, these systems cause filament voltage to vary with power line voltage and transmitter power level changes. Better designs account for filament voltage variation as supply mains (power line) voltage varies, as well as wiring temperature and load power demand variations. Designers should always select the best possible filament voltage to power line voltage relationship, and this relationship must include all causes of filament voltage change over time.

Eimac generally considers +5% or -5% of nominal voltage as an acceptable filament voltage range. Looking at data sheets for the 3-500Z, we see nominal voltage is 5.0 volts RMS, with permissible range between 4.75 and 5.25 volts. The 3CX1200A7 filament is 7.5 volts + - .37 volts, again about 5% plus or minus. Other manufacturers are similar in tolerance. National 811A and Cetron 572B tubes use 6.3 volt filaments, with a specified voltage tolerance of + - 0.3 volts. Once again, tolerance is roughly + - 5% of nominal filament voltage.

If safe filament range is unspecified, +- 5% is a reasonable assumption. It will not be the end of the world if the filament goes outside that range in amateur use, but we should make every reasonable effort to stay within that range. We should always remember that tube life is a combination of many things. Depletion of the filament's ditungsten-carbide layer is one of most frequent problems in broadcast, but one of the least frequent problems in amateur service.

Power Line Stability

In the USA, power line regulation standards vary with suppliers. In general, power mains are supposed to vary less than ~8% worse case. This is nearly the same as saying line voltage typically varies less than +4% or -4% of some nominal voltage. Line voltage variations fit well with tube filament voltage ranges.

We can, of course, have voltages outside that range. It is a good idea to minimize additional voltage drop inside the house, since voltage drop varies with load power and load power varies with the power delivered to the antenna system!

It is impossible to adjust filament voltage properly unless the adjustment procedure includes long term measurement of power mains voltage variations, both in system delivery and under varying equipment current demand. If we see any adjustment procedure in an unregulated filament supply system that does not include allowance for power mains variations or a powerline voltage maximum or minimum limit, the procedure is without value. This is a litmus test for validity.

Tube Life and Amateur Radio Use

In the amateur radio fraternity, we find occasional specific claims that a specified reduction in filament voltage produces a specific tube life increase. This information seems to all go back to a single source, an amateur radio operator in California. It appears he extracted a small slice of data from Eimac filament management programs (extending tube life in AM and FM broadcast service), and spun the small extraction into his own cast-in-stone tube life rule. This rule is blindly repeated as coming from Eimac, and often exaggerated even more in the rewording process.

In this conversion from AM/FM broadcast to amateur use, differences in operation and other more common failures were ignored. Also ignored were multiple warnings and test procedures accompanying Eimac's Filament Management Program, and powerline variations, and other much more common failures.

There are overwhelming differences between AM/FM broadcast and amateur operation. Let's compare a few typical AM/FM broadcast operating parameters directly affecting tube failures to common amateur systems and components:

Typical Operating Conditions or Typically Expected Use Comparison

| Operating problem | AM broadcast | FM broadcast | Amateur SSB | Amateur CW |

| Filament temperature cycling shock. increases chances of open or dislocated filaments | less than once every 168 filament hours | less than once every 168 filament hours | once every 4 filament hours | once every 4 filament hours |

| Internal element heating and cooling cycles. increases chances of element alignment or out-gassing issues | less than once every 24 filament hours | less than once every 24 filament hours | constantly while operating | constantly while operating |

| Emission demand near peak values. prevents reducing filament voltage without increased distortion or splatter, and increasing cathode contamination | almost never | never | common | never |

| Non-use deterioration of vacuum. increases chances of arcing in glass tubes | rare | rare | many hours a year | many hours a year |

| Approach or exceed internal tube element temperature limits. increases chances of internal gas | never | never | fairly common while tuning | fairly common while tuning |

| Filament hours per year. increases yearly filament emission depletion failures | 8750 | 8750 | 500 | 500 |

| Tube Quality. uncontrolled failures due to poor tube materials, processing, or construction | Expensive USA or European tubes with excellent quality, good processing control methods. Reliable | Excellent tube quality, good processing control methods. Reliable | Import cheap tubes. Less-than-ideal material, processing, and testing methods and control | Less-than-ideal material, processing, and testing methods and control |

Considering the profound differences listed above, it's easy to see why tubes in broadcast stations benefit from complex filament management programs. Differences between commercial and amateur use change the type of tube failures each service experiences.

Broadcast yearly filament hours are about 15-20 times higher than nearly all amateur yearly filament hours, and broadcast tubes are babied with almost no thermal shocks or thermal cycles. Commercial broadcast services wear tubes down through emission loss more than anything else.

Tubes in amateur radio applications have much different stresses and running hours, and will not benefit from a rigid, complicated, filament management program. Most amateur amplifiers take decades to equal one-year broadcast station filament hours. The constant thermal cycles and long periods of storage are a lot tougher on tubes. Amateur tubes are also almost always lower-quality foreign tubes.

Because of the profound operational and tube manufacturer quality, amateur tubes have virtually zero failures from excessive filament temperature. This includes amplifiers running far above recommended maximum filament voltage. For example, Dentron amplifiers commonly run 15% or more over recommended filament voltage, yet very few older Dentron tubes suffer emission failures. Many Dentron amplifiers are still using 1970-era tubes, even though Dentron filament voltages are well out of allowable range and Dentron tube cooling is generally pretty poor. This doesn't mean we should run needlessly high filament voltages in amateur service, or not correct grossly out-of-tolerance filament supplies, but it shows how little amateur service stresses emission life. Of course we won't likely be so fortunate when older tubes are replaced with modern imports, but that is a tube quality issue.

If we want to reference an Eimac paper and make changes, we should understand and reference the paper fully and differences between the service discussed in the paper, and the different service we are attempting to apply a document to. We should follow everything the paper tells us to do, and not extract, exaggerate, and misapply one or two lines from pages of information.

Comparison of New 3-500Z Tube Samples

-35 dB PEP IM3 was chosen in the tests below. -35dB PEP is "cleaner" than almost all modern solid state radios, leaving the radio as the primary source of distortion.

Measuring brand new 3-500Z and 3-500ZG tubes produced the following results:

-35 dB PEP IM3 / Saturated Power

Filament voltage regulated at 5.25 volts

High voltage 3000 volts

Drive power at cathode adjusted to obtain saturated power, or -35 dB PEP 3rd order IMD power

Grounded Grid

| Type | Saturated power PEP | PEP @ -35 dB PEP IM3 |

| China 3-500Z | 950 | 775 |

| Eimac 3-500Z | 1050 | 925 |

| Machlett 3-500ZG (1) | 1050 | 900 |

| Triton 3-500Z | 1100 | 950 |

| Machlett 3-500ZG (2) | 1200 | 975 |

| Amperex 3-500ZG | 1210 | 1050 |

Minimum Filament Voltage for -35 dB PEP IM3

-35dB PEP 3rd order, 3000 volts anode. 850 W PEP target (AL80B specification)

| Type | Min filament V RMS | PEP @ -35 dB IM3 |

| China | 5.25 | 800 |

| Machlett (1) | 4.8 | 850 |

| Eimac | 4.7 | 850 |

| Triton | 4.7 | 850 |

| Machlett (2) | 4.7 | 850 |

| Amperex | 4.5 | 850 |

Multiple samples of the same type except Machlett were not available. The Matchlett tubes were the same code date and production run, and matched each other for quiescent current. This does show, for brand new tubes of various brands, minimum allowable filament voltage varies considerably for a given maximum power and distortion.

Dominant 3-500Z Failures in Amateur Service

When Eimac manufactured 3-500Z tubes, the dominant failure was cocked anodes. Welds on one side of the anode would simply let go. Opening a tube, it was evident many welds never fully penetrated the metal. These failures appeared to be periodic weld problems confined to well-defined production batches. The vast majority of tubes, however, would last dozens of years in amateur service. Emission failures over very long usage hours, which is the only thing filament voltage influences, were statistically zero. In order, Eimac 3-500Z failures were:

- Cocked or detached anodes, often clearly visible when the shipping box was opened, sometimes only appearing after many anode thermal cycles

- Broken grid wires, again often visible when the shipping box was opened

- Gas, generally after years of use mixed with long periods of sitting unused

From 1982 until Eimac ended glass tube production, fifty to one hundred 3-500Z's per month went through doors of manufacturers I was associated with. Out of many thousands of tubes shipped and dozens used personally, I cannot recall a single low filament emission field failure except for two cases of customer-induced excessively-low filament voltage on 3CX1500A7/8877 tubes. I recall only one batch of new production 3CX1200A7 tubes with low emission, but that problem showed right out of the shipping box.

Offshore Tubes

The USA does not manufacture nearly as many things, including amateur power level glass vacuum tubes. Varian/Eimac sold the Salt Lake City glass power triode manufacturing to Triton. The last batch of fifty or one hundred 3-500Z tubes under the Eimac name, manufactured after or during the sale, were 100% bad from low anode-to-grid breakdown voltage. That was the end of reliable USA 3-500Z tubes. From the Salt Lake City sale date forward, I never saw a good new-production USA 3-500Z tube.

The difference between Eimac and import tubes centers around processing methods. With Eimac's methods, batches are generally either trouble free, or have the same problem within a batch. This makes it easy to correct problems. Imports use different more "parallel" processing methods, introducing random failures into batches. This makes "weeding out" bad tubes, or tubes with a potentially short lifespan, nearly impossible.

The era of reliable Eimac 3-500Z's ended, and a different failure order began. With no change in equipment design or operating parameters, filament-to-grid shorts suddenly became common. This problem appeared across the board in all products, even in test jigs where filaments were cycled off and on without application of anode voltage. These 3-500Z's were of European manufacture, but even though tubes were "fresh" from the distributor, code dates were years old.

The only other choice was China, which was slowly improving in quality. Initial Chinese 3-500Z tubes actually had high-temperature anode connectors glued on with rubber cement. This was because setscrews were the wrong size! They gradually improved quality and eventually surpassed the European 3-500Z source in percentage of "working tube" delivery. The European source, less able to supply working tubes, was eventually abandoned. Elevated failure rates from mechanical, material contamination, or assembly issues became a "new normal". Higher mortality was offset by reduced cost, although everyone hopes tube quality improves to Eimac levels.

Present day Field Failures

Amateurs, like most other people, want a single fast solution to problems that cannot be controlled. None of us enjoy replacing tubes or having field failures, and despite wild conspiracy theories this includes manufacturers. The forced change to offshore tubes, and the resulting spike in field failures when domestic manufacturing stopped, creates a fertile environment for selling snake oil and magical cures. Part of this is rooted in an unwillingness to believe we are powerless to do anything to correct reduced tube reliability. We want the problem to be someone or something we can actually control or influence. Unfortunately, we also lose common sense when we are desperate for cures. This is made worse when technical publications fail to properly review articles, and present bad information as fact.

Filament voltage concerns are justified in some cases. Some amateur amplifiers have needlessly excessive filament voltage. Voltage at tube pins should generally be within + - 5% of rated voltage under all power line voltage ranges. Voltages outside that range, while not often noticeable in amateur amplifier tube service life, should be corrected.

A properly manufactured filament in a tube free of contaminants can last nearly 10,000 hours at rated voltage. Because of low accumulated filament hours, excessive filament voltage emission loss takes years to show (if it ever does) in amateur service. While there is no question excessive filament voltage accelerates emission loss, accelerated emission loss from excessive filament temperature never shows rapidly. It takes thousands of hours for a good filament, even 10% above rated voltage, to "go soft". We should keep voltage within recommended ranges, but we don't want to assume lowering voltage is the panacea for all tube failures. Accelerated emission loss from excess voltage (occurring thousands of hours out), even in poorly designed filament circuits, is actually one of the least common amateur radio failure modes!

Some information, if we actually read Eimac's filament management program, might surprise us. Correct filament voltage for our applications is not at or near lower voltage limits, unless we are prepared to do a great deal of modification and maintenance work. Reduced voltage filament care guidelines require periodic measurement of distortion and performance. Using minimum voltage requires tightly controlled filament voltage, and monitoring distortion to verify emission has not fallen below safe lower emission limits.

Recently, reducing filament voltage has shown increased presence. A universal formula, apparently created or promoted by a west coast amateur, directly equates heater or filament voltage reductions directly to a precise service life increase. That formula is virtually never true in amateur radio systems! Just as there are special cases where voltage reduction increases reliability, there are cases where filament voltage reduction decreases tube life. There are many more cases where filament or heater voltage changes make no difference at all in service life.

Here is the often misquoted or misapplied Eimac/CPI filament management programs:

Econco filament management Program Link

CPI Eimac Updated filament management Program

CPI Eimac specifies the following conditions in their filament management program. This is copied word-for-word from Eimac's filament management programs related to filament life. Copied Eimac text is boxed with faded red background:

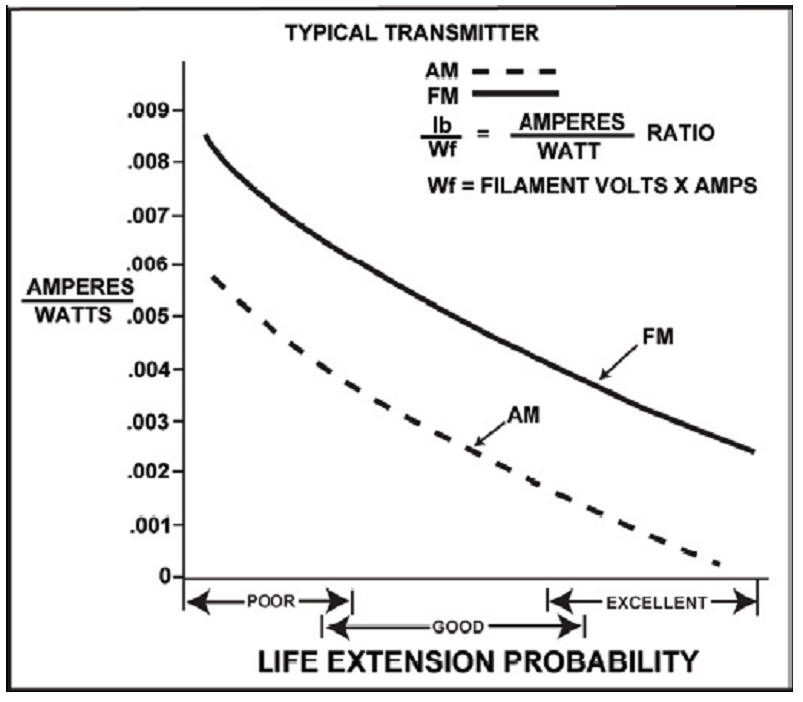

| Figure 1 can be used as a basic guide to determine if a given transmitter and tube combination has a good probability of giving extended life service. Extended life service is defined as useful operating life beyond that normally achieved by operating at rated nominal filament voltage. The amperes/watt ratio is obtained by dividing average anode current by the product of filament voltage and filament current. If the amperes/watt ratio falls in the "good" to "excellent" range, excess emission is sufficient to permit filament voltage derating. At a lower filament voltage, the filament temperature is lowered, thus extending life. A typical FM transmitter on the market today may have an amperes/watt filament ratio of 0.002 to 0.003. This equipment would be considered an excellent choice to achieve extended tube life. On the other hand, if the amperes/watt ratio falls in the "poor" range, it is unlikely that filament derating is possible due to limited emission. Note that this guideline should be used for thoriated tungsten emitters only and does not apply to oxide cathode-type tubes. |

| Figure 1. The probability of extended life service can be determined from this graph. Divide the average anode current in amperes by the product of filament voltage and current. The resulting amperes/watt ratio is projected horizontally to the appropriate curve. The vertical projection to the X-axis indicates the life extension probability. |

First, Eimac warns us to never use minimum voltage life-extension on heater-cathode type tubes. Reducing filament voltage on 8877 or 3CX800A7 tubes (and similar) is a sure way to ruin tubes quickly.

Notice Eimac's text applies ONLY to AM and FM broadcast. There are important differences between broadcast and amateur use.

|

Why does Eimac use average current and filament power

to determine probability of successful life increase with filament

voltage management? Current indicated on amplifier meters is generally plate current and grid current(s). These currents are the average currents, not only over longer periods of time, but also over each RF cycle. Instantaneous peak cathode current in a small tube like a 3-500Z might be as high as several amperes while we see only 400 mA plate current and 125 mA grid current on front panel meters (525 mA average cathode current). The filament-cathode must comfortably supply the instantaneous current, or internal current waveform will change from emission saturation causing peak clipping during each plate current conduction cycle. Peak currents can significantly saturate even if average currents barely change, and remember instantaneous peak grid current adds to anode current demand from the cathode. Peak emission current, in a properly designed and constructed filament, is tied to filament power for that particular construction. Eimac carefully optimizes filament emission for a given filament power (heat), giving them a good idea how much instantaneous peak current an emitter can supply for a given filament power. Proper operation depends on instantaneous peak current, but we cannot directly measure that current in an amplifier. We can, however, measure the effects of not meeting peak current. Those effects would be increased intermodulation distortion when amplifying multiple-tone signals, increased distortion when amplitude modulating a stage, or a decrease in power with a steady carrier. Since SSB or AM has a much higher ratio of instantaneous peak to average current than CW or FM, we need much more emission for a given average current. This is why Eimac tells us to measure distortion on amplitude modulation and power on FM, and that we must watch for changes as filament voltage is reduced. |

Minimum filament voltage is determined by peak emission currents demanded from the tube. If we set filament voltage too low for the required peak current, we can shorten tube life. If we are on SSB or modes producing multiple frequencies at the same time, intermodulation products (splatter) and distortion will greatly increase. Eimac warns reduced voltage must be accompanied through performance verification.

Looking at the above graph for a 3-500Z, we would find an anode current to filament power ratio of .4/75 = .0053. That would work for CW or RTTY by using the FM curve, a steady carrier. There is an excellent chance of tube life increase for a near-continuously operated high-quality 3-500Z tube on steady carrier, or off-on keyed modes. The best candidates for increased life though minimal filament voltage are obviously conservatively operated FM or CW transmitters. The least likely to succeed, amateur SSB transmitters running near full tube ratings.

For SSB, let's just use an average current of .3 amperes. 0.3 / 75 = .004. The AM curve predicts a poor chance of life extension through voltage reduction, SSB logically should similarly less successful. Meeting peak SSB emission current requirements (to minimize splatter) prevents significant filament power reduction unless output power is also reduced. Most amateurs are unwilling to give up 25% of output power to have a tube potentially last 50% longer in emission, especially when it is very unlikely they will ever have a filament-hour emission related failure.

Since Eimac does not give SSB data, I cannot be sure how AM stacks up with SSB. Anything I say about this is a bit of a guess. VK1OD suggests about .007 as the correct number, while I am at about .004.

Looking at the 811A or 572B tube, we find a SSB life extension probability somewhere around .10/25 = .004. Once again we have a low probability of successfully extending tube life though filament voltage reduction below normal specified filament voltage ranges, unless we greatly reduce power. This also, of course, considers the primary failure mechanism depletion of the filament emission over a very long time of steady operation, and not other failures like poor quality or mistuning.

In the real world anything we do to the filament, besides something really bad like excessively low voltage or going over 120%, isn't very likely to change our tube's lifespan, because amateur radio tubes almost never fail from emission depletion. As a matter of fact the only tube's I seen fail from filament voltage have been oxide cathode tubes operated at excessively low voltage. Most directly heated ham tubes fail because the operator is heavy handed when tuning, or the tube is just a bad tube.

CPI/Eimac's filament management program adds the following requirements (directly quoted):

| Instrumentation

Are all tube elements metered in the transmitter? Elements should be metered for both voltage and current, and meters should be red-lined to define operation within safe limits. Modern transmitters may incorporate a microprocessor controlled circuit to monitor all pertinent parameters. In addition, the following controls are necessary if effective filament voltage management is to be undertaken: • Power output metering for an FM transmitter or a distortion level meter for AM equipment • Accurate filament voltage metering; an iron-vane instrument is preferred over the more common average responding RMS calibrated type but true-RMS digital meters are acceptable. • The filament voltage measurement must be made at the tube socket terminals and filament voltage control should be capable of being adjusted in 0.1 V increments. |

From Eimac's filament management program, we see any reduction to minimal filament voltage must be accompanied with the following:

-

Voltage must be accurately measured, monitored, and "red lined" with proper instrumentation, not common meters

-

Power output must be monitored on FM, and distortion monitored with amplitude modulation. This would also apply to SSB

-

Filament voltage must be stable and adjustable, so it can be set at the proper operating point without causing distortion (splatter)

Unfortunately, many amateurs have been misled by a few who have misread, omitted data from, misinterpreted, or misquoted Eimac's filament management programs. Amateur equipment and amateur use often falls well outside Eimac's filament management program guidelines.

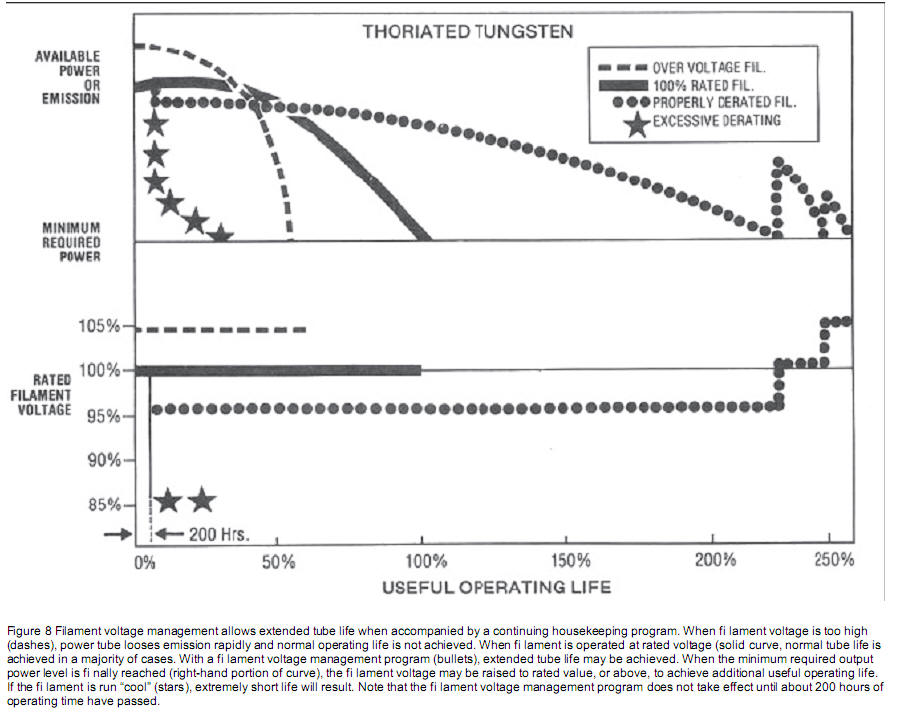

If we actually read and follow Eimac's filament management, we will find the following data. Please pay special attention to the "stars" below, and to what Eimac tells us:

Notice if we set voltage too low, emission life can be as short as 20% of normal. The shortest life curve above is from excessively low filament voltage.

Have you ever saw an article warning about low filament voltage?

Procedures in CPI Eimac and Econco Filament Voltage Adjustment

No amateur can or will follow Eimac's procedure properly. Every instruction I have found, from AG6K's website to the recent QST article, is both improper and greatly over optimistic. Everything I have found instructs setting voltage at minimum allowed voltage without testing intermodulation to confirm adequate reserve emission. Nowhere (except in Eimac's article and here) are consumers warned against excessively low voltage.

If filament voltage is set too low, two potential problems appear:

1.) Intermodulation or splatter increases

2.) Filament life can be greatly shortened, actually more than any other error

Here is Eimac's actual procedure for adjusting voltage:

| When a noticeable change occurs in the output power or if the distortion level changes, the derating procedure must stop. Obviously, operation at and beyond this point is unwise since there is no margin allowed for a drop in line voltage. The voltage should be raised 0.2V above the critical voltage at which changes are observed to occur. Finally, recheck power output or distortion to see if they are acceptable at the chosen filament voltage level. Recheck again after 24 hours to determine if emission is stable and that the desired performance is maintained. If performance is not repeatable, the derating procedure must be repeated. Continuing the Program The filament voltage should be held at the properly de-rated level as long as minimum power or maximum distortion requirements are met. Filament voltage can be raised to reestablish minimum requirements as necessary. This procedure will yield results similar to those shown in the illustration (Figure 8), to achieve as much as 10% to 15% additional life extension. When it becomes necessary to start increasing the filament voltage in order to maintain the same power output, it is time to order a new tube. Filament voltage can be increased as long as the increase results in maintaining minimum level requirements. However, when a voltage increase fails to result in meeting output level requirements, filament emission must be considered inadequate and the tube should be replaced. Don’t discard it or sell it for scrap! Put it on the shelf and save it. It will serve as a good emergency spare and may come in handy some day. Also, in AM transmitters, a low-emission RF amplifier tube can be shifted to modulator use where the peak filament emission requirement is not as severe. |

Eimac's text above obviously requires us to have a periodic schedule of measuring distortion, to keep emission safely above minimum levels. At the time of this writing, I have not found a single amateur article that comes close to proper instructions.

Applying Eimac's Filament Management Program to Amateur Use

Eimac's filament management program applies to commercial transmitters operating with long uninterrupted filament hours, almost always with greatly reduced RF power levels. Extension of operating hours through use of minimal filament voltage works under the following conditions:

|

Without question, all indirectly heated tubes, low quality tubes, and nearly all amateur equipment falls well outside Eimac's guidelines for extending tube life through use of minimal filament voltage. Not only is the equipment used differently and without regulated or controlled filament supplies, virtually no one can or will periodically measure intermodulation to confirm proper operation.

So what does Eimac say, when we cannot meet the above requirements? Here is another unedited quote from Eimac's filament management programs on extending tube life:

|

NOTE: If the filament voltage cannot be regulated to within ± 3%, the filament should always be operated at the rated nominal voltage specified on the data sheet. It should be noted that there is a danger to operating the emitter too much on the “cold” temperature side. It may become “poisoned.” A cold filament acts as a getter; that is, it attracts contaminants. When a contaminant becomes attached to the surface of the emitter, the affected area of the emitter is rendered inactive, causing loss of emission. |

If we cannot regulate the filament, Eimac tells us to run the tube centered on the nominal voltage specified for the tube. Of course we should avoid going outside tube or equipment manufacturer filament voltage limits. Since going below low limit (see graph above) causes shortest life, and since no amateur is going to measure distortion, I set the filament voltage within allowable upper tube filament limits at the very highest line voltage.

A little known or understood fact is I test my amplifier designs extensively over expected line voltage variations for distortion and general performance. Also, if designs go outside ratings, I consult with actual tube design engineers responsible for the tube design. This was done with the 3-500Z back in the 1980's, when Salt Lake produced glass power grid tubes. Everything in the manual regarding tube operation was "bounced off" the proper Eimac tube design engineer, and approved.

In a 3-500Z nominal voltage is 5.0 volts, with recommended a range between 4.75 and 5.25 volts. The design does not allow for operation at voltages below 4.75 volts, yet that is where QST has readers set voltage in a recent article. QST was not responsible enough to check with the designer, read filament management programs, or check with the equipment manufacturer before publishing their article! All information was available, it is not new.

The AL80B, along with all other Ameritron products, have been carefully engineered to not exceed rated filament voltages when the appropriate line voltage tap is used. While it is possible to recover a thoriated tungsten emitter that has been poisoned through low voltage operation, an oxide cathode that has been damaged from low temperature operation is generally not recoverable.

How Do We Set Optimum Tube Filament Voltage?

Incorrect filament voltage, either high or low, reduces filament emission life. The worse condition is excessively low voltage. Other than low voltage induced failures of metal oxide cathodes that can happen in minutes or hours, very few of us will ever experience time-depleted emission in a large transmitting tube. We may witness common emission loss in poorly manufactured import tubes, and on rare occasions even Eimac has a bad batch in their high quality tubes, but few will ever run their tube's emission out through normal amateur filament hours. This is true even when filament voltage is 10% or more high, as we see in older Dentron amplifiers. Still, we should adjust filament voltage properly for our application.

Low Voltage

Excessively low filament voltage causes insufficient cathode emission. This creates three common problems:

1.) loss of linearity during peaks, causing splatter

2.) greatly accelerated emission loss from filament poisoning. This is a more rapid failure than excessive voltage can cause

3.) limited power output (premature cathode current saturation) and/or reduced plate efficiency

Eimac tells us, as do vacuum tube engineering books, we should never run minimal voltage or reduced voltage on a metal oxide cathode tube. Always set a metal oxide cathode tube so minimum filament voltage, at the lowest point in mains voltage, is above the minimum voltage specified by the manufacturer's data sheet.

Directly heated thoriated tungsten filaments can have voltage reduced, but only if we are willing to measure distortion and closely monitor and regulate filament voltage. Very few amateurs will go through such trouble, especially since hours are so low, import tube quality so low, and other stresses so high that virtually no failures come from filament-hour emission loss.

Proper Procedure

First, we must have a good meter. Anyone using an unverified 2% average reading AC meter to fine tune voltage is just deluding himself. We must also measure filament voltage properly at either the time for highest line voltage or time of lowest line voltage, or apply a correction to voltage based on known variations and line voltage at the filament measurement's time.

If filament voltage is too high or low, and we want to optimize filament voltage, we must first make sure the amplifier power mains supply is as stiff as possible. This would include shifting high current loads to 240-volt circuits, and running the largest size wire practical from mains to the amplifier.

After we are sure the mains are as good as reasonably possible, we have to learn our mains voltage variations. This will include spending some time monitoring or periodically measuring line voltage, in particular at primary operating times.

Once we learn the line voltage range and ratio of line voltage to filament voltage on tube pins, we can make adjustments.

The easiest, fastest, and most reliable way to adjust filament voltage is by finding the very highest line voltage ever expected in normal operating times, and adjusting the filament voltage just below the data sheets safe upper operating range limit. This ensures the tube is unlikely to ever go outside a safe limit, and has the most headroom for sag caused by power line loading, transformer heat, and other voltage reducing effects. Unless your amplifier accumulates very uncommon hours of operation, this all you need to do.

If your amplifier has extreme filament hours, perhaps averaging 8 hours daily or more on average, and especially if you run it well below maximum power, you may want to aim for the lowest and highest voltages centered on the nominal data sheet voltage. Personally, I would never bother with this.

QST's October 2011 " The Care and Feeding of a 3-500ZG Amplifier " article comment link

| Repeatedly the Ameritron manual warns users always disconnect the amplifier from power mains before removing the cover. Repeatedly, the manual warns customers never to defeat the interlock. Repeatedly, the manual warns customers never to power up the amplifier with the cover removed. |

In the AL80B, the following measurements occur:

|

Using AL80B instruction manual

125-volt maximum line settings |

|||

|

Line voltage |

Article test point |

Filament pin voltage (cold) |

Filament pin voltage (hot) |

|

124.1 |

5.32 |

5.21 |

5.15 |

At maximum line voltage for the AL80B's Instruction Manual tap setting, with a warm amplifier, filament voltage is 5.15 volts. This is well within the tube manufacturer’s allowable range of 4.75 to 5.25 volts

| 245-volt maximum voltage settings with a cold amplifier | ||

|

Line voltage |

Article test point |

Filament pin (cold) |

|

246.2 |

5.36 |

5.25 |

Again, the AL80B is within specification when the proper power transformer taps are selected. In the AL80B, measure power line voltage over time. Wire the transformer for the maximum expected line voltage.

I specified setting voltage in Ameritron amplifiers for the highest possible line voltage. The ideal minimum from that voltage would be about 8% less. This means the 125 volt tap keeps the filament in range from 115 to 125 volts. Setting for maximum line voltage does two things:

-

Filament voltage stays below recommended maximum values

-

Filament voltage will not go below the measured value where typical 3-500Z's deteriorate in intermodulation performance

The normal filament voltage range for a 3-500Z tube is given in widely available data sheets. The documented filament voltage range is 4.75 to 5.25 volts, not some voltage invented by random people.

AL80B Filament Voltage Compensation

When I design shared filament/HV transformer systems, I include special transformer design considerations. I consult with some of the best transformer design engineers available, and one of the best was Ernie Smith from Schumacher Electric. Ernie and I worked to constantly improve transformer designs.

The AL80B, like most amplifiers I design, uses optimum internal placement of windings, core size, and primary design. The design focuses on the filament system, where filament center tap voltage balance and filament voltage stability with transformer load variations is paramount.

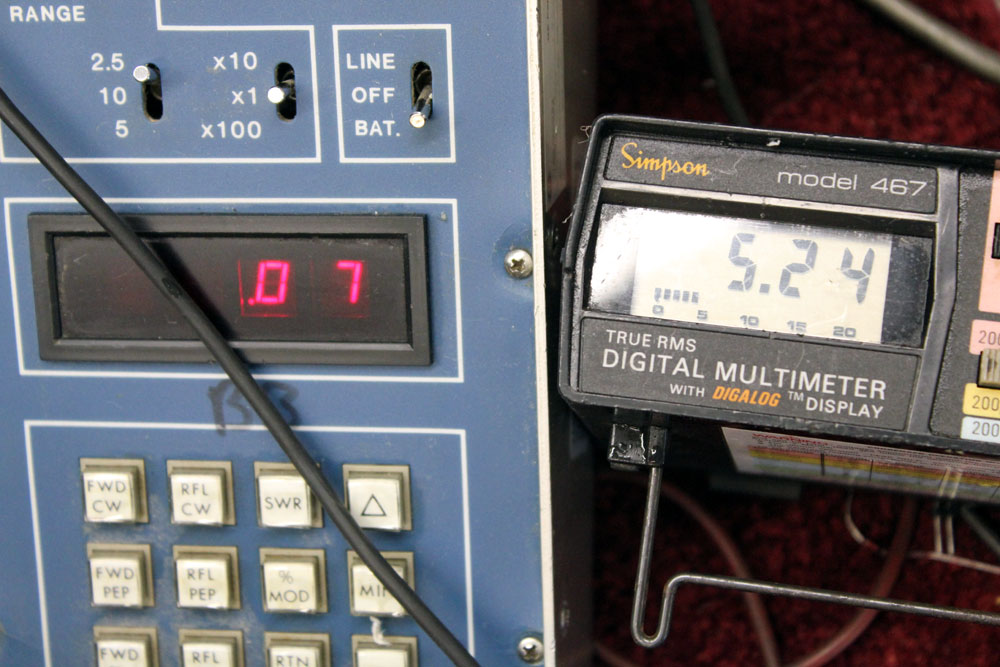

The AL80B is remarkable for a single transformer design. With a reasonably good power line, AL80B filament voltage typically changes less than 2% from no load to 1.3 kilowatts DC load on the power supply. For example, using my 124.5-volt line (at that moment) and the 125-volt maximum voltage transformer taps, I measured a filament voltage change on a typical digital meter from 5.24 volts no load to 5.16 volts with 1.35 kilowatts DC load on the 3-500Z filament/plate transformer. A taught-band meter, generally better for RMS voltage measurements, shows no filament voltage movement at all. We can be reasonably sure filament heat changes less than 2% from no-load to full-load in the AL80B if power mains are reasonably good.

This is exceptionally good regulation for a combination filament/high voltage transformer. This system had hundreds of hours of careful thought and measurement.

Correct Filament Measurement Methods

It is actually not necessary to measure filament voltage in Ameritron amplifiers. That work has already been done for customers. All you really need to know is your outlet's highest line voltage. You simply look in the manual, and select transformer primary wiring closest to but still above the highest line voltage. That completes the job. With 14 voltages available, there is little reason to cobble up the amplifier by adding a coil of hookup wire (that also unbalances the transformer center tap).

The procedure below can be used in other systems to measure filament voltage. It is not for unskilled people, and you should always consult the manufacturer of your equipment whenever possible before making any changes. The intention below is a demonstration of proper measurement techniques. They do not necessarily apply to other systems.

While measuring AL80B filament voltage is generally unnecessary, a relatively safe method would be:

- Unplug the amplifier

- Verify zero volts on the HV meter

- remove the cover

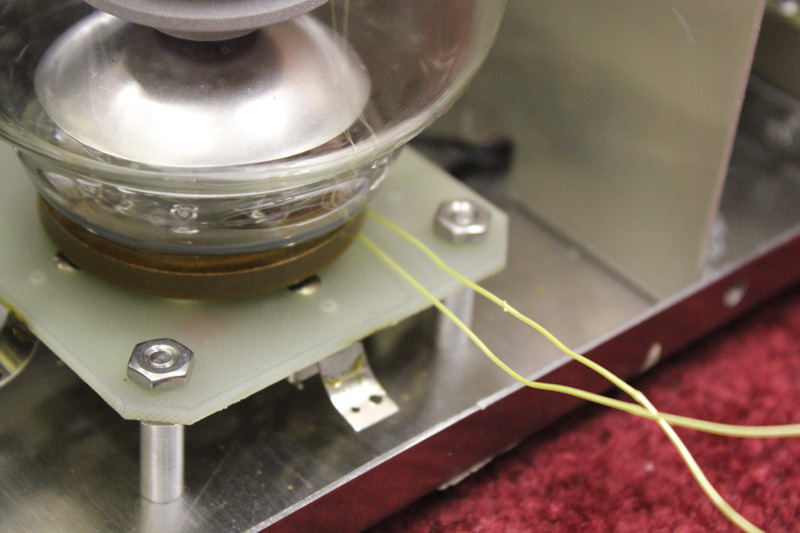

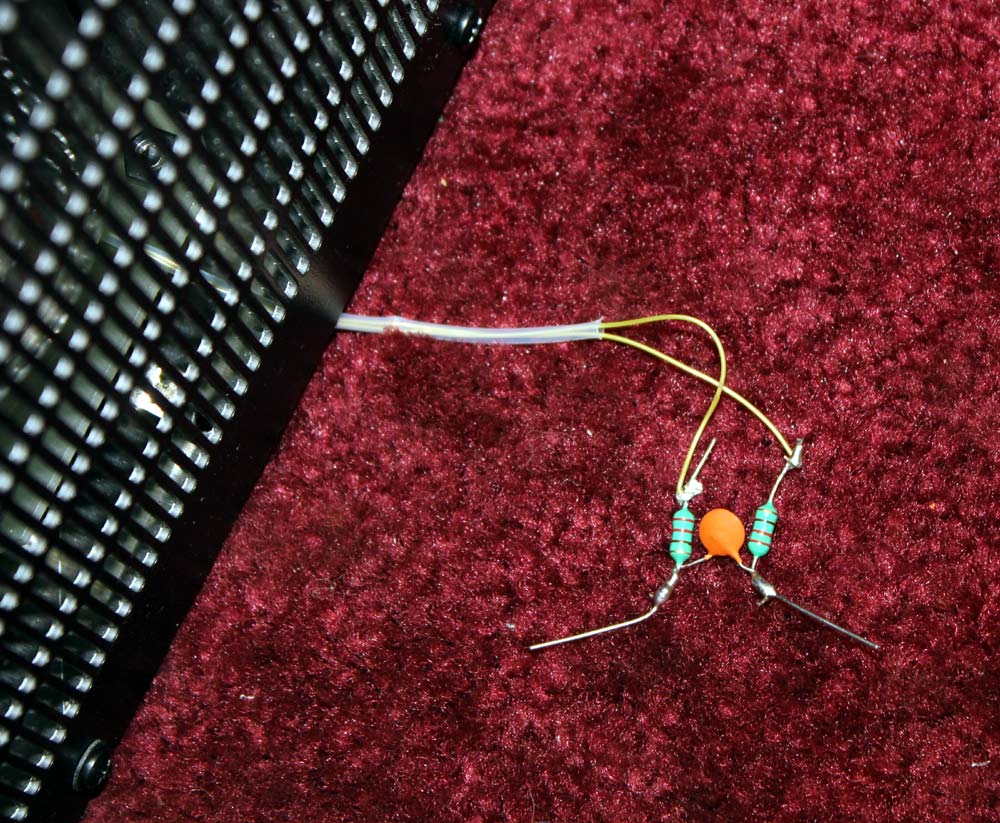

Using very small Teflon or high temperature insulation wire-wrap wire, pre-form the ends to be tight around tube pins

Make sure pins are clean, but do not scrape plating off pins or solder to pins

Slide wires over the filament pins. They should firmly fit

With tube in socket, wires exit like this

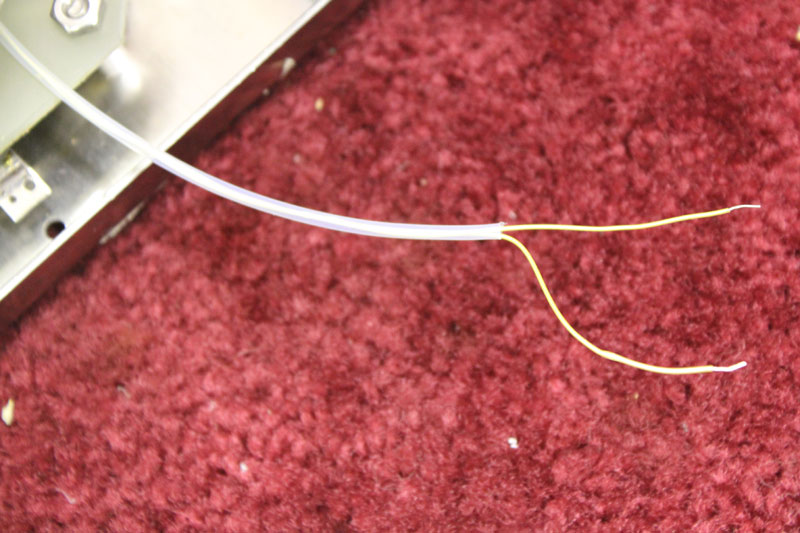

Sleeve the wires with an additional protective sleeve

This prevents damage or shorts when cover is installed

To confirm connections, measure wire to wire resistance while wiggling wires

Resistance should be low and remain low compared to meter input impedance

Reinstall cover and replace screws

Do not over-tighten and crush test wires

Install an RF and transient filter

Series components are 220 µH RF chokes

Shunt component is .1 µF capacitor

- Connect the filament meter across the capacitor

- Use either an accurate analog AC RMS meter, or a true-RMS digital meter

- Most digital meters are average-reading types calibrated in RMS

- Connect the amplifier to the mains. Meter wiring must not be touched beyond this point; filament voltage can rise to several hundred volts if a tube arcs

- Turn on power

- High voltage should come up around 3000 volts

- This is the voltage that will kill when amplifier cover is removed

- Never power the amplifier up without a cover

- Never defeat the interlock

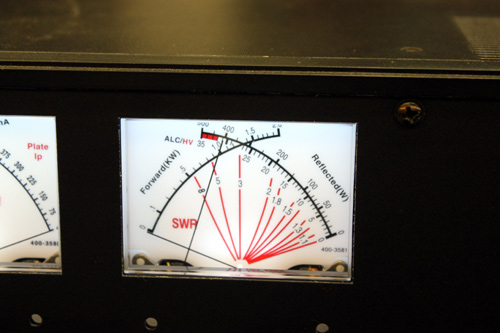

- Measure filament voltage on a TRUE-RMS meter with no load at your highest line voltage

- I use a verified calibration meter, since most meters are 1-2% tolerance

In this case on the 125-volt transformer setting, with 124.5-volts on my power line,

filament voltage was 5.24 volts no load

this was with a cold amplifier, voltage will decrease about 1% at operating temperature

- be sure filament voltage is measured or noted

- it can be adjusted to correct for line voltage range at your location

- voltage should close to but under 5.25 volts as possible at your maximum line voltage

- this assures the tube does not "splatter" on SSB

- when line voltages are low or when the tube ages, and that

- filament voltage never goes over the maximum filament voltage recommended

If your power line voltage sags more than ~10% during certain times of the day, in particular if your tube is a little low on emission, there may be a slight increase in intermodulation products (splatter). This can be avoided by running about 20% less peak power when line voltage is more than 10% below maximum setting.

Summary

Information regarding tube life and filament voltage in amateur publications is sometimes nether safe nor reliable. Measurement methods are generally wrong, target filament voltage are often wrong, and life change predictions are almost always grossly exaggerated. Measuring pin voltage is sometimes not even necessary if instruction manuals are followed and maximum power mains voltage is known. For example, the AL80B has fourteen different line voltage settings available. Ameritron amplifiers built after 1990, and most Ameritron amplifiers manufactured before 1990, have multiple voltage taps for filament adjustment. Do not reduce filament voltage by adding resistors or extra filament wire length. Measure your actual maximum line voltage and wire transformer taps according to the instruction manual.

- Adding wire or resistance to one side of the filament path is also not advisable if filament voltage should ever be high.

- Reducing filament voltage to values suggested in some articles can seriously shorten useful tube life, and increase signal bandwidth on SSB.

- Never connect an amplifier to mains with a cover removed, and never defeat an interlock.

Watching tube failure problems constantly, most tube failures center around operator error, poor tube manufacturing quality control, and poor manufacturing and testing techniques at tube manufacturers. I don't expect anyone to realize an amateur service tube life increase by reducing filament voltage. Eimac's Filament Management Program shows a "poor" life extension probability from filament management in amateur-type applications. I agree, especially in light of the fact no one is going to constantly monitor distortion, filament voltage, or anything else.

Link to QST Article

copyright 2011 W8JI